Material

| Muviri | Aluminium (5052) ● | Simbi | Simbi isina ngura | |

| Finish | Yakanatswa | Zinc Plated | Yakanatswa | |

| Mandrel | Simbi ● | Simbi isina ngura | Simbi | Simbi isina ngura |

| Finish | Zinc Plated | Yakanatswa | Zinc Plated | Yakanatswa |

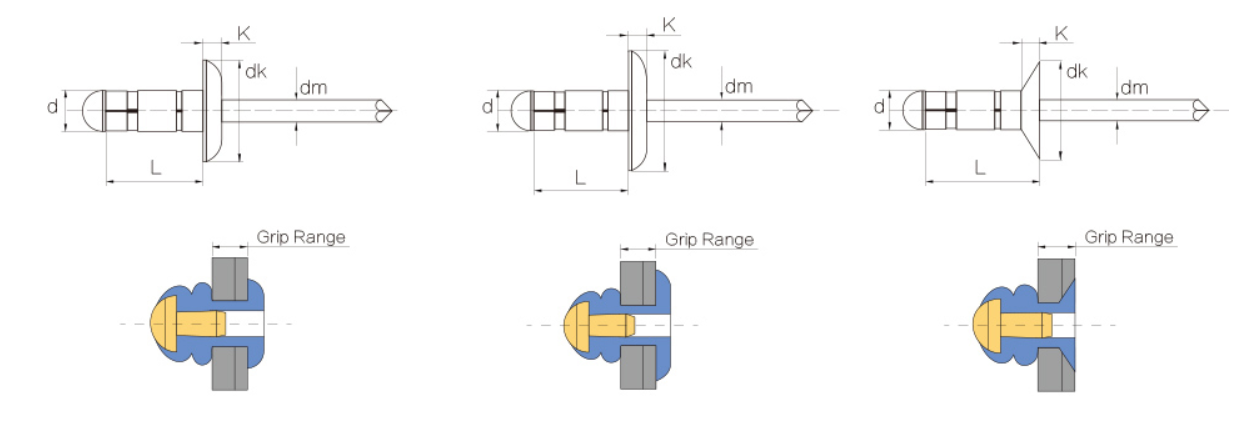

| Musoro Type | Dome, CSK, Hombe Flange | |||

Tsanangudzo

| D1 NOM. | DRILL NO.& HOLE SIZE | ART.CODE | GRIP RANGE | L (MAX) | D NOM. | K MAX | P MIN. | SHERA LBS | TENSILE LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 1/8" 3.2mm | #30 3.3-3.4 | ASMG42 | 0.031-0.134 | 0.8-3.4 | 0.283 | 7.2 | 0.252" 6.4 | 0.051" 1.30 | 1.06" 27 | 135 600N | 202 900N |

| ASMG43 | 0.031-0.187 | 0.8-4.8 | 0.331 | 8.4 | |||||||

| ASMG44 | 0.046-0.250 | 1.2-6.4 | 0.390 | 9.9 | |||||||

| ASMG45 | 0.156-0.312 | 4.0-7.9 | 0.453 | 11.5 | |||||||

| ASMG46 | 0.216-0.375 | 5.5-9.5 | 0.516 | 13.1 | |||||||

| ASMG47 | .250-0.437 | 6.4-11.1 | 0.610 | 15.5 | |||||||

| 5/32" 4.0mm | #20 4.1-4.2 | ASMG52 | 0.020-0.125 | 0.5-3.2 | 0.283 | 7.2 | 0.312" 7.9 | 0.063" 1.60 | 1.06" 27 | 213 950N | 337 1500N |

| ASMG54 | 0.046-0.250 | 1.2-6.4 | 0.390 | 9.9 | |||||||

| ASMG55 | 0.125-0.312 | 3.2-7.9 | 0.453 | 11.5 | |||||||

| ASMG56 | 0.156-0.375 | 4.0-9.5 | 0.516 | 13.1 | |||||||

| ASMG57 | 0.250-0.437 | 6.4-11.1 | 0.610 | 15.5 | |||||||

| ASMG58 | 0.250-0.500 | 6.4-12.7 | 0.681 | 17.3 | |||||||

| 3/16" 4.8mm | #11 4.9-5.0 | ASMG64 | 0.062-0.250 | 1.6-6.4 | 0.421 | 10.7 | 0.386" 9.8 | 0.071" 1.80 | 1.06" 27 | 296 1320N | 450 2000N |

| ASMG65 | 0.079-0.315 | 2.0-8.0 | 0.492 | 12.5 | |||||||

| ASMG66 | 0.125-0.375 | 3.2-9.5 | 0.587 | 14.9 | |||||||

| ASMG67 | 0.187-0.437 | 4.8-11.1 | 0.610 | 15.5 | |||||||

| ASMG68 | 0.250-0.500 | 6.4-12.7 | 0.681 | 17.3 | |||||||

| ASMG610 | 0.345-0.590 | 9.0-15.0 | 0.783 | 19.9 | |||||||

| ASMG612 | 0.500-0.781 | 12.7-19.8 | 0.992 | 25.2 | |||||||

Application

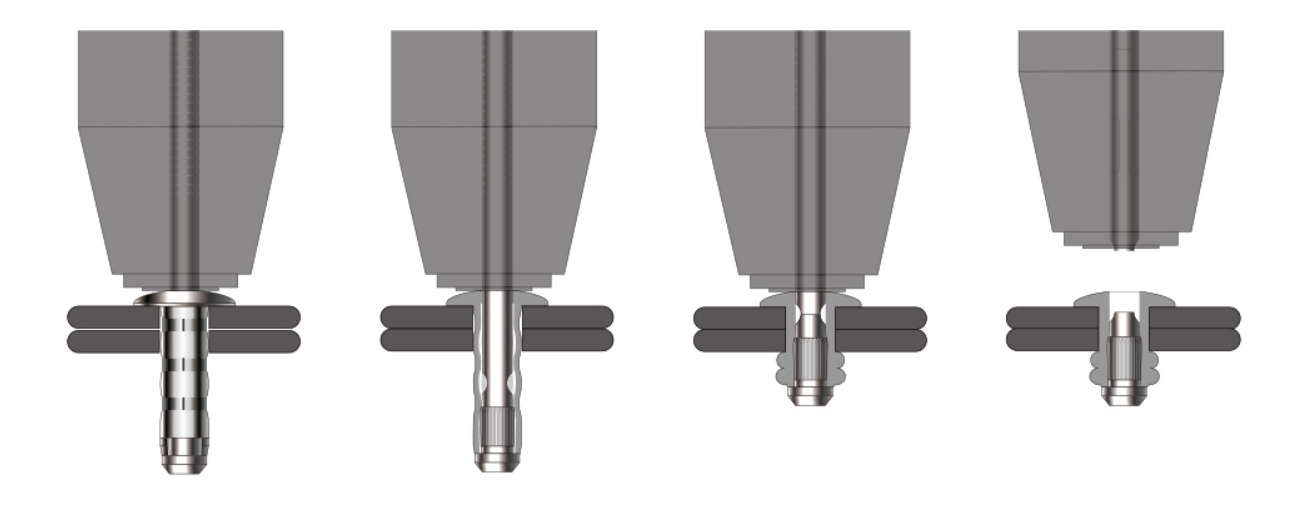

Multi-Grip rivets ane hupamhi hwekubata.Munguva yeriveting, iyo rivet musimboti inodhonza magumo emuviri werivet kuita kaviri dhiramu chimiro, inosunga nhengo mbiri dzezvimiro kuti dzisimbiswe zvakasimba, chisimbiso chakagadziridzwa chekudzivirira kwemamiriro ekunze uye kuderedza kudzvanywa kuri pamusoro penhengo dzezvimiro.Multi-grip pop rivets inowanikwa mune zvealuminium, simbi uye Stainless Simbi, uye ine sarudzo yemusoro wedome, csk musoro uye hombe flange musoro.

Chishandiso: Multi-grip blind rivets anonyanya kushandiswa kukwira akasiyana siyana akaonda zvimiro zvikamu mumotokari dzakasiyana, ngarava, kuvaka, michina, zvemagetsi, mudziyo, aluminium makesi, makesi emidziyo uye mamwe maindasitiri.

Iyo pop rivet imhando yeriveting chikamu, chakakodzera riveting yezvinhu zvakawanda.Iine simba rekutsanya rakasimba.Panguva imwecheteyo, zvinhu zvinoshandiswa zvakanakisa, uye danho rekugadzira rakanyanya kukwirira.Kuita kwepop rivet inogadzirwa kunowedzerwa

Kunyanya kurapwa kwepamusoro kwepop rivets kunosanganisira:

1. Electroplating process: common surface treatment process inogona kushandiswa pazvikamu zvakawanda zvesimbi.Electroplating process inoshandiswa pamapop rivets, anogona kudzivirira pop rivets uye kudzivirira kubva pakupfeka kana kuora.

2. Paint baking process: kunatsiridza kunaka kwepop rivets, uye gadzira mavara akasiyana zvinoenderana nezvinodiwa.Iwo mavara akajeka uye haasi nyore kupera, ayo anogona zvakare kuchengetedza pamusoro pepop rivets kune imwe nhanho.

Nekuvandudzwa kweindasitiri yemazuva ano, pop rivets haangori akakwana mukuita, asi zvakare akanakisa pakutaridzika, ane yakanaka yekushongedza maitiro, uye anosimudzira zvishoma nezvishoma kuwedzera kwechikamu chekushandiswa kwepop rivets.